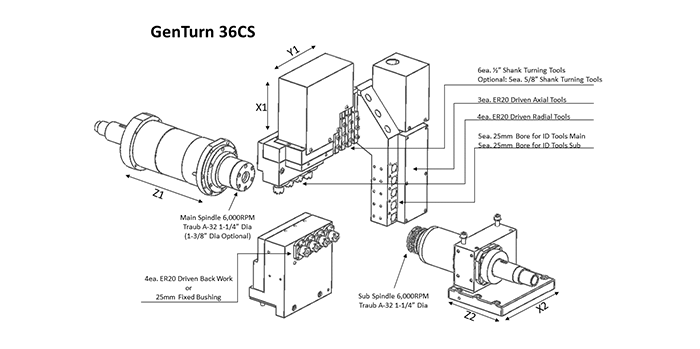

36-CS

7-Axis CNC Swiss Machine Without Guide Bushing

- L36 mm 1-3/8” Bar Capacity

- LDual “C” Axis and “Y” Axis with 19” Travel

- L27-Tools with 11-Driven Tools

- LSimultaneous Main & Sub-Spindle CNC Swiss Machining

- LParts Catcher and Chip Conveyor Included

- L1,181 Inch per Minute Rapid Rates

$0.00 Down Financing

Machine Specifications

Main Spindle

Maximum RPM / Spindle Bearing | 6,000 RPM / 5 Bearing Spindle, 3 Front, 2 Rear ø110 mm |

Spindle Motor | 10 HP 3,000 RPM spindle Motor, 2:1 Pulley Ratio |

Collet Nose | Brown & Sharpe #22 or Traub A-32 |

Drawtube Bore | 1.456” (37 mm) |

Maximum Barstock Diameter | 1.25” (32 mm) Standard 1.375” (36 mm) with Adapter |

X-Axis Travel | 7.28” (185 mm) |

Y-Axis Travel (true Y-Axis, not compound Y) | 19.29” (490 mm) |

Z-Axis Travel | 6.50” (165 mm) |

Rapid Travel Speed: X, Y, Z | 1,181 IPM (30 m / min) |

Minimum Input Unit | 40 millionths (0.00004”) (0.001 mm) |

OD Turning Tool Positions | 6 OD Tools (1/2” or 12 mm) (5-5/8” Tool Plate Available) |

ID Turning Tool Positions | 5 ID Tools |

OD Turning Tool Size | 1/2” or 12mm (5/8” or 16 mm Optional) |

ID Turning Tool Bore Size | 25 mm |

Spindle Center Height | 40” (1,015 mm) |

Sub Spindle

Sub Spindle RPM/Spindle Bearing | 6,000 RPM / 4-Bearing / Quad-Duplex Pair Configuration | |

Sub Spindle Motor | 5-HP 3,000 rpm Spindle motor, 2:1 pulley ratio | |

Collet Nose | Brown & Sharpe #22 or Traub A-32 | |

Maximum Barstock Diameter | 1.250” in Collet Chuck (1.080” (27.5mm) Pass Thru) | |

X-Axis Travel | 11.53” (293mm) | |

Z-Axis Travel | 11.61” (295mm) | |

Minimum Input Unit | 0.0001” (0.001mm = 40 millionths inch) | |

ID Turning Tool Bore Size | 25mm | |

Air Blast Nozzle | Included | |

Finished Parts Ejector | Included, Along with Parts Catcher & Parts Conveyor Belt |

Live Tooling

Cross Slide Live Tools | 4-ER-20 Cross Slide Live Tools, 4,000 RPM, 2.0 HP (1.5 kw) |

Front Slide Live Tools | 3-ER-20 Front Slide Live Tools, 4,000 rpm, 1.0 HP (0.75 kw) |

Live Tool Collet Size | ER-20 Collet, Ø1/2” (0.5 – 13 mm) Tool Shank Capacity |

Max RPM for Live Tools | 4,000 RPM (1 cross live tool can be substituted on subspindle tool block) |

Machine Dimensions

Machine Length | 101” (2420mm) ( *+ 36” for Chip Conveyor) |

Machine Depth | 68” (1500mm) |

Machine Height | 80” (1985mm) |

Machine Weight | 8,000lbs (3,628kgs) |

Coolant Pump | Dual 50psi 3/4-HP Coolant Pumps for Main and Subspindle |

Coolant Tank Capacity | 63-gallon Coolant Tank, with Coolant Flow Confirmation Sensor |

Lubrication Distribution | Way Lube Distributed at 3-6 cc / 15-minute Cycle |

Machine Power Requirements | 220vac ±5%, 63-amps, 3-phase, 60Hz |

Air Requirements | 85-PSI at 10-CFM for Parts Catcher, Parts Ejector, & Air Blast |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.