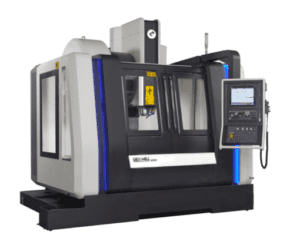

Expand Machinery’s GENMILL – 4024 combines strength with speed for optimum productivity, and features travels of 40.5” in X, 23.6” in Y, and 25.6” in the Z-axis. The rigidity of the massive Meehanite processed cast iron frame provides a high-strength cutting platform with superior vibration dampening and efficient metal removal rates. The 12,000 RPM 25-HP direct-drive in-line #40 taper spindle features rigid-tapping and includes a thermostatically controlled spindle-oil cooler. The dual-contact precision ground “Big-Plus” spindle provides enhanced rigidity, superior concentricity, increased tool life and greater cutting capability; along with excellent tool length repeatability. The machine uses precision pretensioned roller bearing guideways to provide nearly twice the rigidity of ball bearing ways for enhanced cutting performance and the 1,417 IPM rapid rates make for reduced cycle times. A fast 1.7-second tool-to-tool change time is combined with a 30-tool twin-arm automatic tool changer. An included 300-PSI through-the-tool coolant system is also included for more efficient chip removal and extended tool life. A host of helpful standard features that others charge extra for are included with the machine.

The Mitsubishi M830 control features High-Speed Machining and includes Super Smooth Surface Control to provide superior surface finish. The control processes 270,000 blocks-per-minute with 2,700 block look-ahead by using a high-efficiency ultra-high-speed 64-bit fiber-optic backplane and an advanced RISC processer designed exclusively for CNC machine tool use. Mid-program restart capability is another standard feature along with a 32GB solid-state data-server, providing ample part program storage. A 3-year control, motor, and drive warranty from Mitsubishi provides long-term peace-of-mind for the end user.

The combination of the high-speed machining features in the M830 CNC control and the enhanced metal cutting attributes of the high-performance Big-Plus spindle and other listed enhanced machine characteristics combine to create a more productive metal removal environment. Soderberg Manufacturing, in Walnut, CA, experienced a cycle-time reduction from 40-minutes to 14-minutes when they switched an aerospace job to their GENMILL – 4024 and witnessed more efficient chip removal utilizing the volume milling features this this machine provides as standard features.

Expand Machinery offers the Ganesh CNC line-up of vertical milling machine starting at 24” x 16” and going up to 100” in X and 39” in Y in 9 sizes. Auto power shut-off and 4th and 5th axis prewire are all standard features with the entire Expand Machinery VMC machine series. Expand Machinery also produces cutting edge CNC Swiss machines and multi-tasking CNC lathes with 3/4” to 3” bar capacity. Expand Machinery has extensive capabilities in production analysis, automation and turn-key solutions in support of challenging production applications. Expand offers a complete line of CNC and manual milling and turning machines to meet your needs. A new 40-page catalog presents the entire Expand Machinery machine tool lineup showing solutions that will provide you with greater manufacturing efficiency. You can also see the complete Expand Machinery machine tool line-up at www.expandmachinery.com