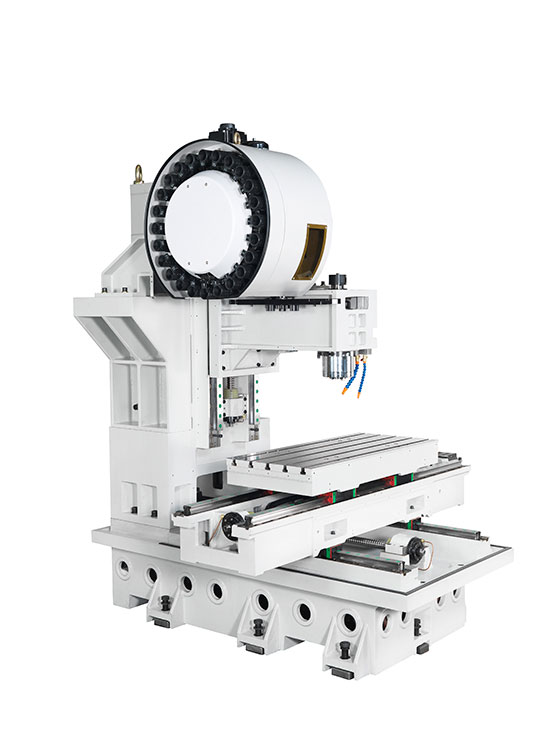

4024

40.55″ X 23.62″ 3 Axis High Speed Vertical Machining Center

- L30 Tool High Speed Double Arm ATC

- L1,417 Inch per Minute Rapid Rates

- LSpindle Chiller for Consistent Thermal Stability

- L300 PSI Through-the-Tool Coolant System

- L2,700 Block Look-Ahead High-Speed Machining

- L4th & 5th Axis Wiring

$0.00 Down Financing

Machine Specifications

Axis Travel

X-Travel | 40.55” 1,030 mm |

Y-Travel | 23.62” 600 mm |

Z-Travel | 25.59” 650 mm |

Spindle Nose to Rotary Table Surface | 5.1”– 30.56” 130 – 775 mm |

Spindle Center to Z-axis way covers | 22.83” 580 mm (throat dimension) |

Table

Table Size (L x W) | 45.66” x 19.68” 1,160 mm X 500 mm |

T-slot width (5 T-slots total) | 0.709” slot width 18 mm wide on 100 mm centers |

Max. Table Load | 3,530 lbs 1,600 kgs for full accuracy |

Spindle

Spindle Motor – S1 / S2 / S3 = 11 / 15 / 18.5 kw | 25 HP Peak, 20 HP 30 min duty-rating spindle |

Spindle Speed – Inline Direct-Drive | 12,000 RPM (15,000 RPM optional) |

Spindle Torque | 90 ft-lb @ 1,500 RPM |

Tool Type | CAT #40 Taper (BT #40 optional) |

Spindle Taper Material / Hardness | SCM415 / HRC 58 – 62 |

Spindle Runout | ≤ 0.000040” T.I.R |

Spindle Bearings – Front | 110 mm NSK 70BNR 2-P4 class-7 bearings |

Spindle Bearings – Rear | 110 mm NSK 70BNR 2-P4 class-7 bearings |

Retention System / Holding Capability | Bellville Spring Stack 1,650 – 1,760 lbs |

Retention Knob (pull stud) | C40-4502H (coolant) Japanese Standard |

Axis Feeds

Accuracy X, Y, & Z axis (JIS6338) | ± 0.0002” / 12” ± 0.005 mm over 300 mm travel |

Repeatability X, Y, & Z axis (JIS6338) | ± 0.0001” / 12” ± 0.003 mm over 300 mm travel |

Least Input Command Increment | 0.0001”/ 0.000040” 0.001 mm / (40-millionths in metric) |

Rapid Traverse – X, Y | 1,417 IPM 36 m / min |

Rapid Traverse – Z | 1,260 IPM 32 m / min |

Cutting Feedrate | 0.02 – 393 IPM 10 m / min |

Axis Drive Motor Power – X, Y | 5 HP, 3.5 kw |

Axis Drive Motor Power – Z | 5 HP, 3.5 kw |

Ballscrews – X, Y, Z | 40 mm ballscrews 12 mm pitch |

Tool Changer

Tool Capacity (30 + 1) | 30-Tool Twin-Arm |

Tool Shank | CAT#40 Taper (BT#40 optional) |

Tool Change Time | 2.2 sec tool-to-tool |

Maximum Tool Diameter / w/adjacent tool | 5.90” / 3.15” 150 mm / 80 mm |

Maximum Tool Length / Weight | 11.81” / 15 lbs 300 mm / 7 kg |

Tool Selection / Tool Access | Random access / Bi-directional shortest path |

Specifications

Air Service Requirements | 85 PSI @ 14-scfm |

Coolant Capacity / Pressure | 97 gallons / 300 PSI 367 liters / 20-bar |

Connected load electrical requirement | 33 KVA 220 vac ±5%, 60-Hz |

Floor space requirements (W x D x H) | 115” x 82” x 116” (add 48” on left side for conveyor) |

Machine Weight | 15,708 lbs 7,120 kg |

Warranty – 1-year machine warranty | 3-year Mitsubishi control, motors, & drive warranty |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.

Expandmachinery.com | 818.349.9166 | Copyright © 2015-2024 Expand Machinery, LLC. All Rights Reserved.