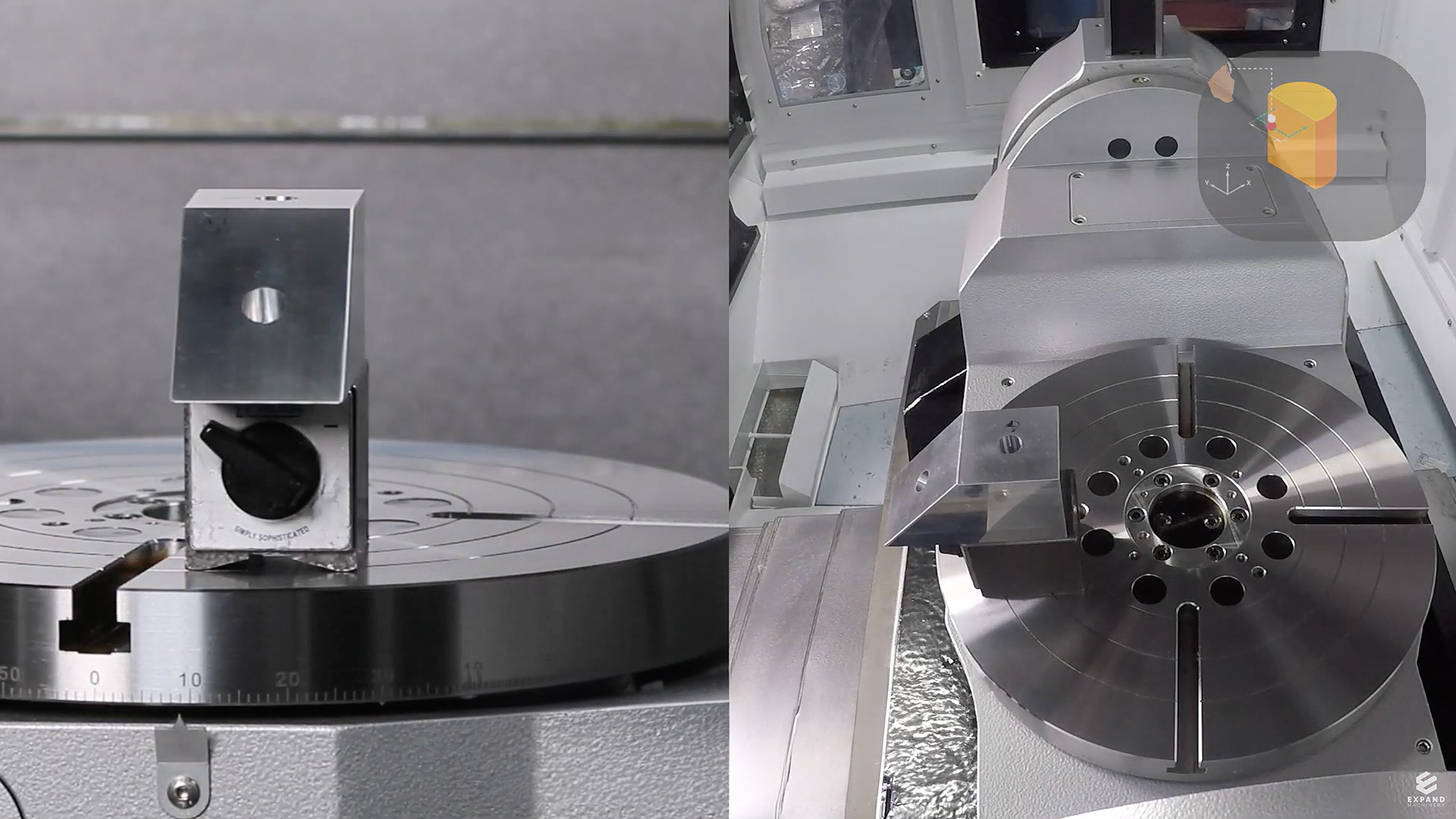

With the Mitsubishi Incline Surface Machining and Tool Center Point Control on the Expand Machinery 5-Axis Machining Centers, we can easily place the fixture anywhere on the table and in a few quick measurements, using the Renishaw graphical interface, square up the fixture, pick up the G54 datum on the material, and run the part program. Greatly reducing setup time.

The Mitsubishi Incline Surface Machining (Also referred to as Dynamic Offsets) lets you machine a part without positioning the part at a precise location in relation to the machine’s tilt point. Expand machinery technician set the tilt point of each machine accurately using Renishaw Axiset. Your software can use Euler Angles, Roll Pitch Yaw, 3 Points on a Plane, 2 Vectors, Projection Angles to define multiple planes all referencing one single G54 location on the part anywhere in the work envelope.